×

- HOME

- ABOUT US

- OUR SERVICES

- OUR PRODUCTS

- Elevator Cabins

- Elevator Cabin Models

- Coating Types

- Ceiling Models

- Floor Types

- Elevator Doors

- Automatic Elevator Doors

- Automatic Folding Cabin Doors

- Manual Elevator Doors

- Manual Elevator Doors - Custom

- Elevator Machine Engines

- Elevator Machine Motors - MR

- Elevator Control Panels

- Elevator Rails

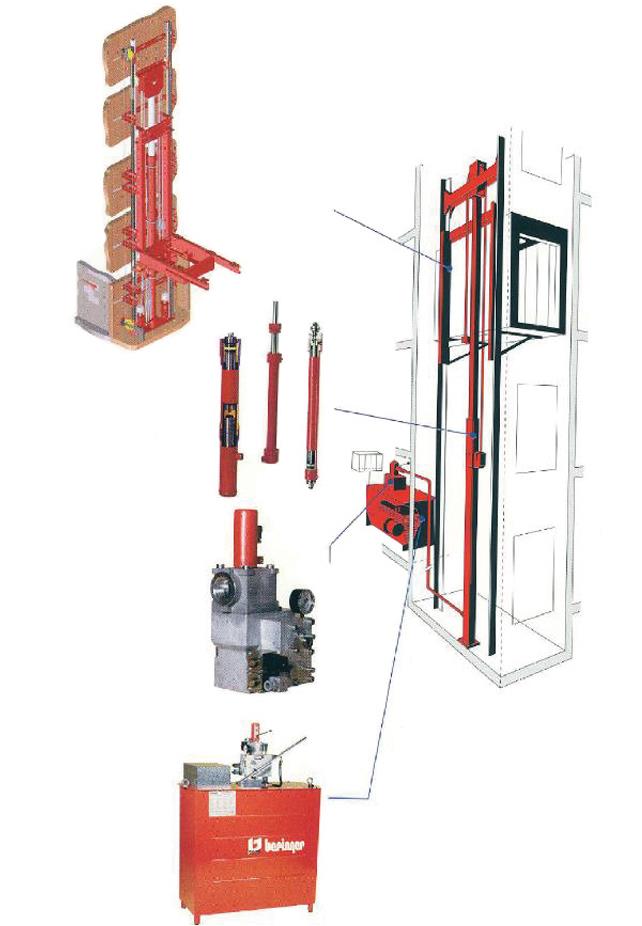

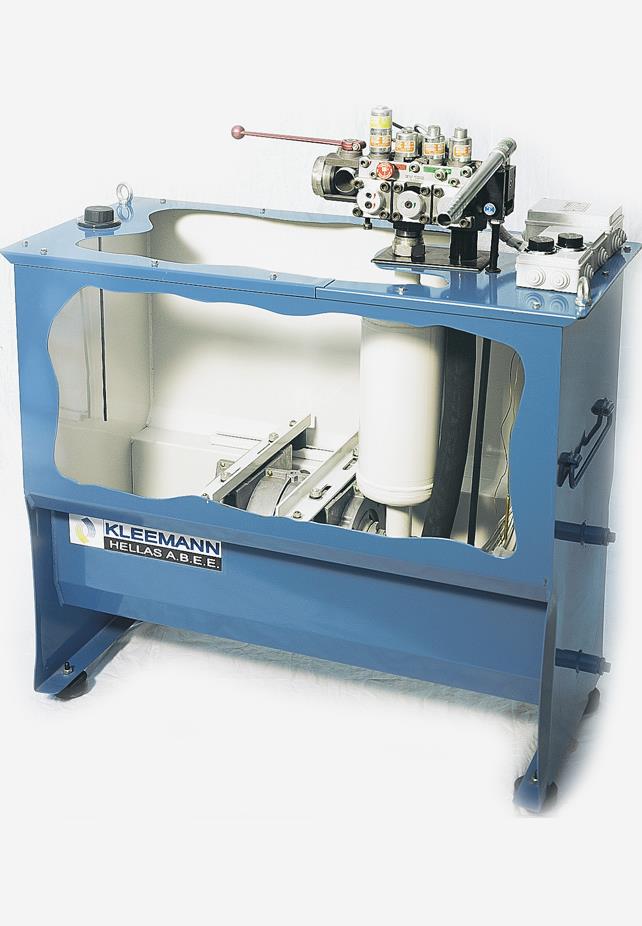

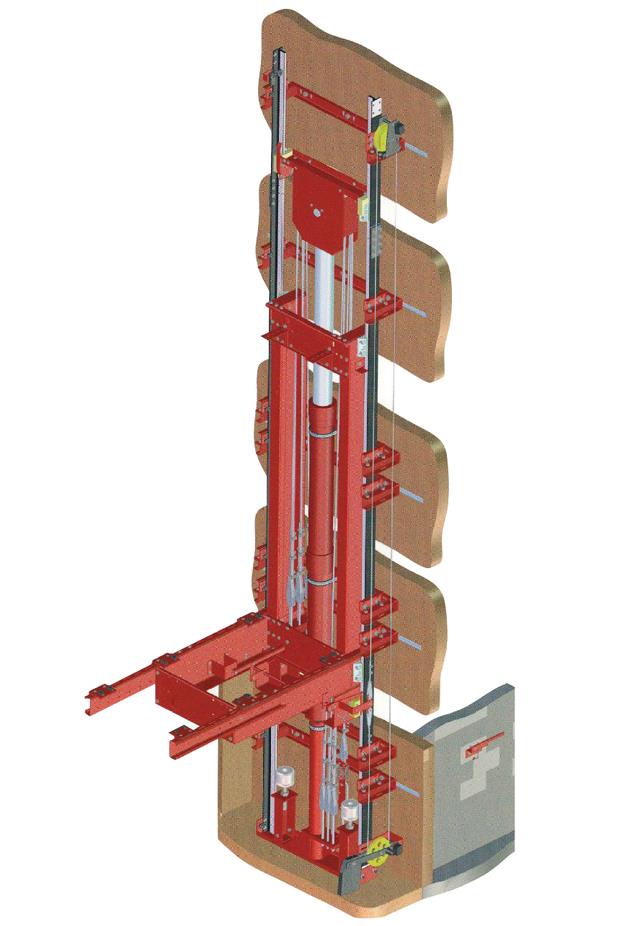

- Hydraulic Lift Systems

- Butonlar

- Other Elevator Parts

- Elevator Steel Ropes

- Elevator Door Locks

- Cables

- Skates and Plastics

- Cabin Bumpers

- Elevator Weights

- Elevator Pulleys

- Elevator Regulators

- Other Elevator Materials

- ELEVATOR DIVERSITY

- GALLERY

- NEWS

- CONTACT

☰ Menu

Design your elevator Design

Design your elevator Design